November 2022

I have already discussed the tour of Parmigiano Reggiano, but on the same day spent Cooking with Stefania we visited two more food production locations.

Prosciutto di Parma

It was in 100 BCE that Cato the “Censor” first mentioned the extraordinary flavor of the air-cured ham made around the town of Parma in Italy. It is still a gift of the gods.

The hams are made from the rear haunches of the pig. The curing is controlled carefully so that the ham absorbs only enough salt to preserve it. By the end, a trimmed ham will have lost more than a quarter of its weight through moisture loss, helping to concentrate the flavor.

Producers of Prosciutto di Parma receive fresh legs from authorized slaughterhouses on a weekly basis; the average weight is around 33 pounds. However, I have heard they are attempting to increase these to around 35 – 40 pounds.

After a quick trim, the legs are salted by a maestro salatore, (salt master): the pigskin is covered with humid sea salt, while the muscular parts are covered with dry salt.

The leg is then refrigerated at a temperature ranging from 33°F to 4o°F, with a humidity level of approximately 80% for about a week then gets a second thin coating of salt which is left on another 15 to 18 days. depending on weight. Salt is the only preservative used in the processing method.

Next, the hams hang for a period ranging between 60 and 90 days in refrigerated, humidity-controlled rooms, at 75% humidity where the meat darkens.

The hams are washed with warm water and brushed to remove excess salt and impurities, then hung in drying rooms for a few days.

Now the hams are hung on frames in well-ventilated rooms with large windows that are opened when the outside temperature and humidity are favorable. The weather of Parma allows this air drying, and it is what many say makes Prosciutto di Parma, Prosciutto di Parma. By the end of this phase, which lasts about three months, the exposed surface of the meat has dried and hardened.

The exposed surfaces of the hams are softened with a paste of minced lard and salt in order to prevent the external layers from drying too rapidly.

At the end of the aging period, which is by law at least 1 year starting from the date of first salting (and some may be cured as long as 3 years), a horse bone needle, which rapidly absorbs the product fragrances, is inserted in different parts of the ham and smelled by experts looking for impurities.

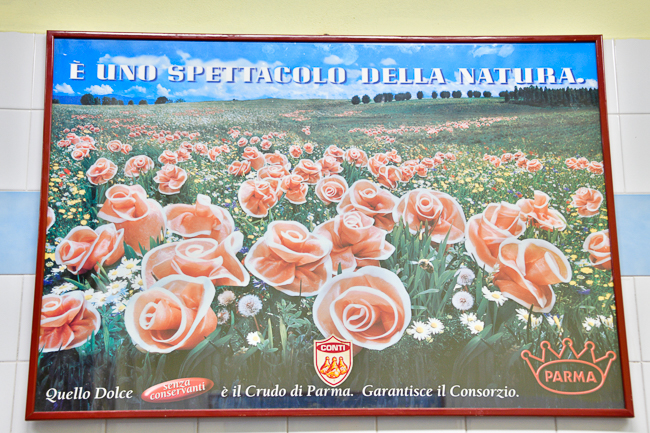

Parma ham is highly regulated and to bear the name Prosciutto di Parma it must bear the Ducal Crown.

Aceto Balsamico

Making Balsamic Vinegar is a lesson in patience. The grapes are crushed, producing a must, then boiled down to one-half or one-third of their original volume. Only Trebbiano, Lambrusco, and Ancellotta grapes can be used in the production of Balsamic Vinegar of the coveted Modena or Regio Emilia PDO. The must is poured into barrels that have been rinsed with boiling vinegar and left to age for a year.

At the end of the first year, the now-syrupy liquid is put in wooden kegs.

The wood used varies and each wood gives the Balsamic a unique flavor. Woods include chestnut, ash, juniper, cherry, mulberry, and traditional oak.

During the aging phases, tradition calls for the barrels to remain open at the “cocchiume”, the traditional hole in the center of a barrel.

Usually, (but not always) a battery of wooden barrels for the production of traditional balsamic is made of an odd number, between 5 and 9 barrels which vary in their capacity. The size of a traditional set of barrels goes from a capacity of 18 gallons used at the beginning down to a capacity of as little as 3 gallons for the final stage.

The aging process of Balsamic Vinegar DOP of Modena and Reggio Emilia requires a minimum of 10 years. The process requires temperatures above 68 degrees F to activate the necessary bacteria; these temperatures are also necessary for the evaporation of excess water. At the same time, cold is necessary to avoid excessive evaporation to allow sedimentation of unwanted solid residues on the bottom of the barrel.

These climatic conditions are continually found in the Provinces of Modena and Reggio Emilia, which are characterized by cold winters and very hot summers. So while the area is known for its Balsamic from professional bottlers, you will find many home attics serving as vinegar cellars for families and friends.

Every year the vinegar is decanted into smaller barrels. If the finished product of the last barrel of the battery has aged long enough to be considered ready. The remaining content from the penultimate barrel is moved into the smallest, sometimes the penultimate receives what remains in the third, and so on. An extra large barrel is kept with the must over the years in order to continually fill the largest of the battery.

The age of the Balsamic is key. A ten-year aged bottle is fine for salads, but considering the price of the older years, the usage becomes important. Just a few drops of a 40-year Balsamico is absolutely divine over a chunk of aged Parmigiano Reggiano cheese or stirred into a panna cotta.