November 17, 2022

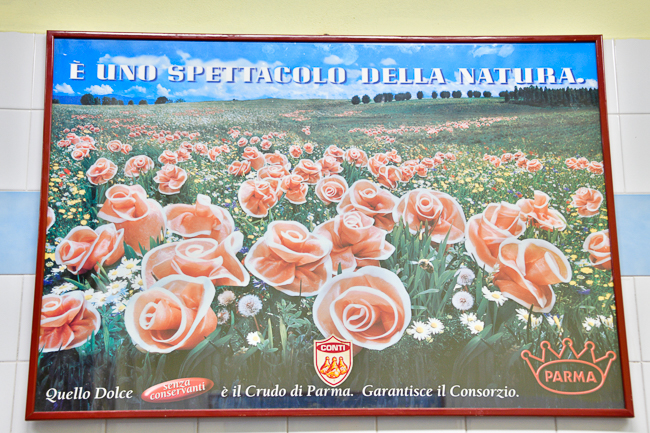

The City of Parma is lovely but you come to Parma for Parmigiano Reggiano, Prosciutto di Parma, and Aceto Balsamico.

We spent one full day with Stefania of Cooking with Stefania, and I mean a whole day. We began in a Parmigiano Reggiano factory, proceeded to Stefania’s house to cook lunch, then visited a Parma Ham factory and her family farm that produces Balsamic Vinegar. We began at 8:30 in the morning and the sun was well down when we parted ways. It was a glorious, educational, and incredibly tasty day.

This post is all about cheese.

Parmigiano Reggiano

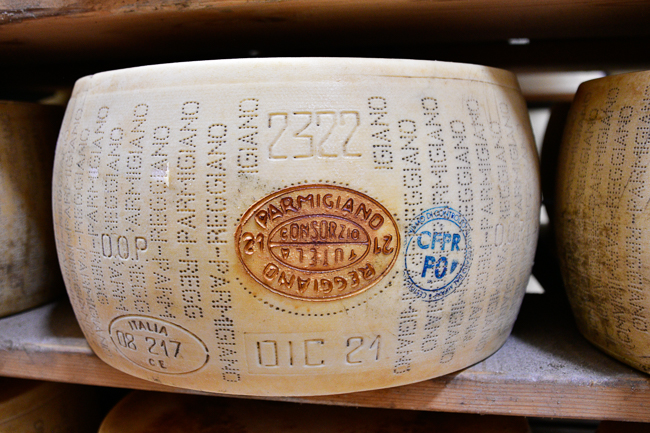

Many cultures around the world are trying to protect their native foods and Parmigiano Reggiano is no different. Parmigiano Reggiano cheese is a product with the Protected Designation of Origin (PDO). Cheese produced according to the rules of the organization is the only cheese entitled to bear the Parmigiano Reggiano mark and, therefore, the wheel must display all the marks required for identifying and distinguishing the product.

The most important is the very first step. Only raw milk produced in the area can be used to produce Parmigiano Reggiano cheese. Nothing can be brought in from other areas, this includes any type of food given to the cows. There are some 3000 farms in the Parmigiano Reggiano area.

The Italian Frisona is the most common breed among Parmigiano Reggiano producers. Imported from Holland, it is known as Friesian because the original stock is found in the Dutch region of Friesland. The first cattle were brought to Italy at the end of the 19th century. In the 20th century, cattle from Italian breeding farms were introduced, thus Italian Frisona. The other types of cows found in the region are White Modenese, Brown Cow, and Vacche Rosse.

The funny thing is, you will never see cows driving around the area. The land must be used to harvest the food for the cows and is too valuable to waste letting cows graze. Cows will be found inside large concrete barns that you begin to recognize once someone explains this all to you.

The minimum maturation for Parmigiano Reggiano is 12 months (the longest minimum maturation for any PDO cheese), and 18 months for export, but Parmigiano Reggiano reaches its height at approximately 24 months and yet it can mature from 36 to 48 months, or longer.

The milk from the morning and the previous evening is poured into the traditional upturned bell-shaped copper vats. It takes about 145 gallons of milk to produce each wheel of Parmigiano Reggiano. The milk slowly and naturally coagulates with the addition of rennet and a whey starter, which come from the previous day’s processing.

The curd must reach the proper consistency as determined by an experienced cheese maker.

Once the curd is the proper consistency it is broken into miniature globules using a traditional tool called “spino”.

Before going any further the master cheese maker tests, by hand, if the curd has reached the perfect consistency.

Then heat is introduced bringing the milk to 130 degrees F, causing the cheese granules to sink to the bottom of the cauldron forming a single mass.

After about fifty minutes the cheese maker lifts the cheese up using a linen cloth, then ties it off onto a crossbar for easier access.

This large mass of cheese is cut into two parts, wrapped in the typical linen cloth, and placed in a mold that will give it its final shape.

A casein plate with a unique code is applied to each wheel making it possible to trace every wheel of cheese back to its origins at any time and from anywhere.

After a few days, the wheels are immersed in a salt solution salting the cheese through osmosis.

After 12 months, every wheel of cheese is tested by the Consortium. Each wheel is tapped with a hammer, and the ear of an expert has the final say.

The conforming wheels are marked with the hot-iron brand and become Parmigiano Reggiano. We won the lottery the day we were at the factory. Stefania said she had only seen the process twice in all her time as a guide, and there was the branding man (not the inspector, he had already done his job) marking the wheels that will be considered good enough to carry the Parmigiano Reggiano name.

*

While everyone considers Parmigiano Reggiano as a grated cheese on pasta, the truth is, I prefer it broken off into chunks so I can pop them into my mouth and actually get the grainy texture and the subtle flavors. Add honey or 40-year-old balsamico and it is heaven.

A little something interesting…if Parmigiano Reggiano is aged for at least 12 months the lactose breaks down making it a lactose-free cheese.

This particular factory also makes Ricotta and all unused milk by-products are fed to the pigs, which is another part of the business.

A few more pictures from the branding process.