April 2024

Zellij Tile

Morocco isn’t Morocco without the Zellij tile.

Zellij is a style of mosaic tilework made from individually hand-chiseled tile pieces. The pieces were typically different colors and fitted together to form various patterns, most notably elaborate Islamic geometric motifs such as radiating star patterns. This form of Islamic art is one of the main characteristics of architecture in the Western Islamic world.

Zellij Tile in a Madrassa

After the 15th century, traditional zellij fell out of fashion in most countries except Morocco, where it is still produced today.

Zellij tile on a horseshoe arch

Zellij on the floor

Stone

Stone

Muqarna vaulting is often compared to stalactites or honeycombs.

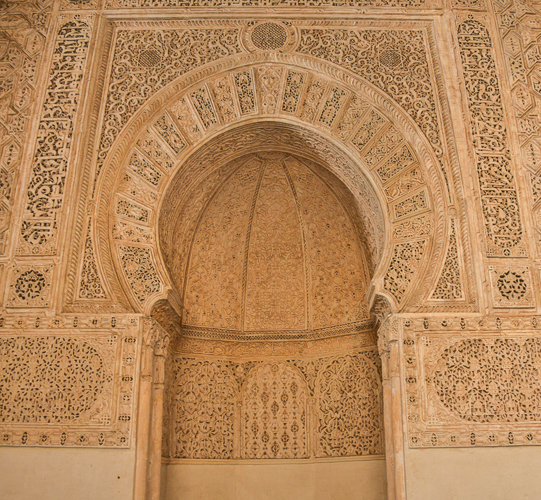

A horseshoe arch adorned in carved stone.

Brass

Brass doors and lamps are found all over the Islamic world.

*

Star design found in the ornamentation of a brass door.

Tile

Green roof tiles are the predominant roofing choice in much of Morocco.

Wood

One of the more assertive characteristics of Moroccan architecture is the Tazouaqt, or the art of traditional painting on wood. In cities known for Tazouaqt, such as Fez and Marrakech, wooden works are not considered completed until painted.

Tazouaqt

An unpainted wooden ceiling

Flat Plaster

Tadelakt

Tadelakt is a waterproof plaster surface used in Moroccan architecture to make baths, sinks, water vessels, interior walls, especially in hammams and exterior walls (as shown here), ceilings, roofs, and floors. It is made from lime plaster, rammed, polished, and treated with Black Soap to make it waterproof and water-repellent.

Black Soap

Black Soap, or Olive Soap, is added to speed surface carbonation and impart water resistance. The soap chemically reacts with the lime plaster, forming lime (calcium) soaps. Calcium soaps are insoluble in water and fairly hard.

You will find this type of plaster finish world,wide and it is done differently in every place.

In Morocco, the traditional application technique is:

- Mix plaster powder with water for 12 to 15 hours prior to the addition of pigment.

- Apply the plaster in one thick coat with a wooden float, and smooth the plaster with the same.

- Before the plaster sets, use a flat, smooth, hard stone to compress the plaster, then a plastic trowel for the final polish.

- After that, polish using stones or abrasives harder than the plaster, to provide a smooth, sometimes shiny, finish.

- And finally, seal with a black soap solution.

Long-term maintenance of tadelakt requires regularly resealing the surface with a soap solution.

Carved Plaster

Carved plaster is, to me, one of the most awe-inspiring architectural elements in Islamic art.

This is called Gebs, the Arabic word for gypsum, the mineral that makes up plaster.

The most widespread application is for geometric designs. Arabic calligraphy is also a common application to express passages from the Qur’an or poetry. Plaster is so well adapted to be carved in organic, curvilinear forms that decorations of highly stylized scrolling vines, leaves, and flowers are one of the more common designs found using this medium.

Today, since Gebs is mostly used in interiors, Plaster of Paris, or a low-fired gypsum plaster is used. At a minimum, the plaster should be applied to a thickness of 3/4″; however, some applications of up to two inches thick can be found. Gypsum plasters have an initial set anywhere from mere minutes to a few hours. The plaster application is typically carried out a day before the carving begins. Depending on ambient humidity, the plaster will take a week or two to install fully. It is highly workable during this time, and the working time can be extended if necessary by continuing to wet down the plaster each day. The initial set renders the surface hard enough to carve while the moisture content within keeps it workable and prevents it from becoming too brittle and prone to fracture.

*

*

*